RP serial Linear Position Sensor for Hydraulic Cylinder

Features :

♦ Rugged and reliable edge, oil and corrosion resistant

♦ Linear measurement, absolute value output

♦ LED lamp diagnostic function

♦ High accuracy, high Resolution

♦ modular and generalized design, easy to maintain

♦ Noncontact measurement, no abrasion

♦ Low energy consumption, low temperature drift

Technical parameter

Optional interface | analog | SSI | Start/stop |

Output signal | 4~20mA,; 0~10V ect | 24, 25, 26 bit binary or gray code | Pulse signal |

Optional interface | Modbus | Profibus-DP | CAN bus |

Output signal | RTU signal, standard EIA-RS485/RS422 | DP protocol | CANopen,CANbasic |

Measuring range | 50~5000mm | ||

Performance | Non-linearity < ±0.01%F.S. (minimum ±50μm), repeatability < ±0.001%F.S. (minimum ±1μm) | ||

Operating Voltage | 24VDC (-15/+20%) overvoltage protection, reverse polarity protection | ||

Working current | <60mA (varies with the range) | ||

Installation method | Cylinder built-in installation, M18*1.5, M20*1.5, 3/4-16UNF or customized | ||

Protection class | IP67 or IP68 | ||

Operating temperature | - 40℃~+85℃ | ||

Stem material | Stainless steel 304, 316 | ||

Measuring rod pressure | 35MPa continuous/70MPa peak | ||

Dimension

Installation

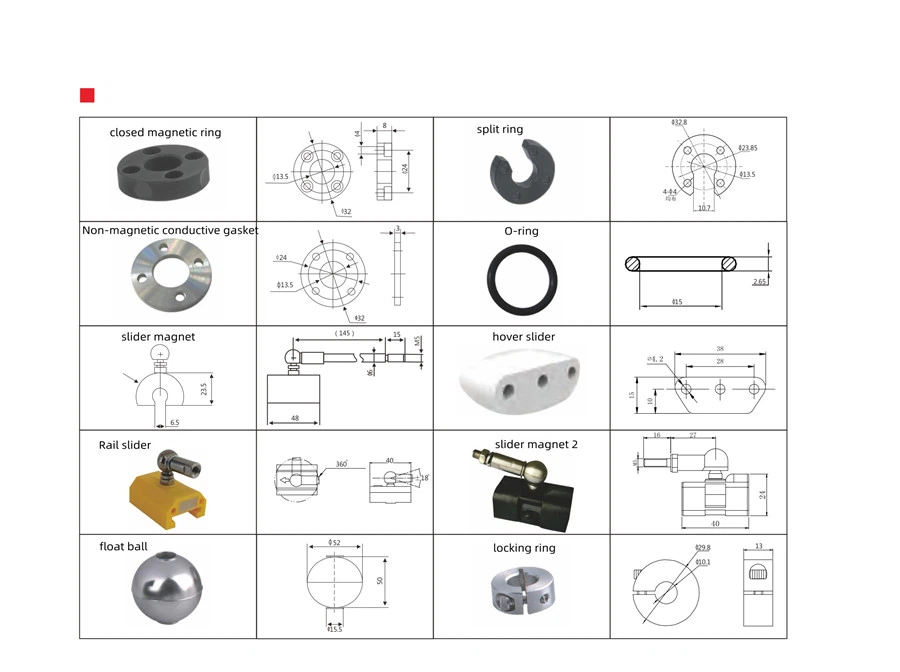

Part list

Type | Name | Quantity |

Position sensor | Magnetic ring/slider | 1 |

special screw | 4 | |

washer | 1 | |

Non-magnetic conductive gasket | 1 | |

liquid level sensor | Float ball | 1 |

locking ring | 1 | |

Hexagon socket screws | 1 |

Application

♦ hydraulic control system, metallurgical equipment, wind power generation

♦ engineering machinery, rubber machinery

♦ port machinery, injection molding machine

♦ hydroelectric power stations, solar power plants, real-time monitoring of the reflection angle

♦ flight simulator

Package

Paper tube with carton

Workshop

FAQ

Q: Are you manufacturer?

A: Yes, We are professional sensor manufacturer over 20 years! Our technical team has more than 5engineers.

Q: Can you accept OEM service ?

A: Yes, we can put your company information and logo on our sensors.

Q: Can I be your distributor?

A: Yes, we are looking for distributors in oversea market.

Q: What is your lead time?

A: Normally 7-10days. For quantity above100pcs, need extra 3-5 working days.