BRG-100B Dynamic Torque Transducer

Product Introduction

Our dynamic torque sensors measure dynamic torque on rotating shafts, enabling real-time monitoring and measurement of torque changes during the motion of rotating components or mechanical systems. Based on the principle of strain measurement, they use strain gauges to sense the strain on the rotating shaft, generating a tiny electrical signal. After amplification and processing, the output signal reflects the magnitude and changes in torque on the rotating shaft. Characterized by high precision, high-frequency response, multi-channel measurement, and high reliability, they are widely used for dynamic torque measurement in automotive engines, transmissions, aircraft engines, propellers, manufacturing equipment, and research.

1. This product integrates a resistance strain gauge sensor and an integrated circuit, offering high precision, stable, and reliable performance.

2. It outputs forward and reverse torque signals.

3. Both ends are keyed.

4. It can reach a speed of 300 RPM, with a maintenance cycle of 10 million revolutions.

Technical Parameters

|

Range |

0-200,300,500,1000,2000Nm |

|

Accuracy |

±0.1,±0.2%FS |

|

Zero Temperature Effect |

±0.03%FS |

|

Span Temperature Effect |

±0.03%FS |

|

Compensated Temperature Range |

-10~60ºC |

|

Operating Temperature Range |

-20~75ºC |

|

Torque Output |

1.5mV/V±10%F.S. |

|

Supply Voltage |

5-10VDC |

|

Input resistance |

350±20Ω |

|

Output resistance |

350±10Ω |

|

Response frequency |

100μS |

|

Insulation resistance |

≥2000MΩ/100VDC |

|

Safety overload |

150% F.S |

|

Extreme overload |

200%FS |

|

Material |

Shaft material 17-4PH stainless steel, housing is aluminum |

|

Electrical connections |

Red/E+, Black/E-, Green/S+, White/S- |

|

Special shaft length |

Customizable |

Drawing (mm)

Aviation Plug

Standard aviation plug, plug-and-play, easy installation

High-quality Bearings

Strong mechanical fatigue resistance, good hardenability, capable of high-speed, long-term operation, output forward and reverse torque signals, and strong anti-interference capabilities

High-quality Core Components

Excellent stability, high detection accuracy, and high-precision engraving

Used for dynamic torque measurement in automotive engines, transmissions, aircraft engines, propellers, manufacturing equipment, and research.

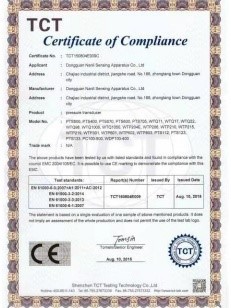

Honor and qualification

Official certification, professional after sales service.

Certificate name

Certificate name

Certificate name

Certificate name

Certificate name

Equipment

Package

Each sensor is protected by a tight sponge and packed in a separate hard box. There is no need to worry about the sensor being damaged during long-distance or long-term transportation.

The torque sensor can be equipped with a transmitter and a display to suit different outputs..

FAQ

Q: what is the lead time ?

A: Normally the lead time is about 5 working days.

Q: Can you customize ?

A: No, the dimension should be our standard . But we can suggest you to choose the right one.

Q: How can you arrange delivery ?

A: For small quantity , we can send by air express ,such as DHL, UPS, Fedex . For big quantity , we can arrange delivery by sea cargo .

Q: About samples:

A: Yes, we have stock for samples.

Q: About guarantee:

A: 12 months

Q: What information do you need to choose the right dynamic torque sensor ?

A: Please provide the torque range , Max speed , torque and speed output signal , cable length .