BRG-MK003 Force Measurement Module

- The output signal is not affected by the position change of the force application point.

- Good linearity and high measurement accuracy.

- Suitable for simultaneously measuring tensile and compressive forces.

- Small size, light weight, easy to install and maintain.

- Simple structure, good sealing, long-term stability, and durability.

- Typically consists of a top plate, base plate, weighing sensor, load bearing column, and bolts

- Available in fixed and floating installation types.

- Uses a shear beam load cell as the force sensing element, measuring strain to determine weight.

- There are connectors for lead wire extraction at the fixed end of the sensor.

- They have threaded holes in the top and bottom plates for connecting components.

The cantilever beam design allows for a compact yet robust weighing module suitable for various harsh environments, with high accuracy and stability in measuring tensile and compressive forces simultaneously.

Technical Parameter

|

|

||

|

Rated quantitative schedule |

T |

0-60 |

|

Output sensitivity |

mV/V |

2.0±0.002 |

|

Zero point output |

%F.S. |

±2 |

|

Non-linear |

%F.S. |

0.05 |

|

lag |

%F.S. |

0.03 |

|

Repeatability |

%F.S. |

0.03 |

|

Creep (30 min) |

%F.S. |

0.03 |

|

Temperature sensitivity drift |

%F.S./10℃ |

0.03 |

|

Zero temperature drift |

%F.S./10℃ |

0.05 |

|

Response frequency |

Hz |

1k |

|

Material |

42CrMoA/stainless steel |

|

|

impedance |

Ω |

700/1400 |

|

Insulation resistance |

MΩ/100V DC |

≥5000 |

|

Use voltage |

V |

5-15 |

|

Operating temperature range |

℃ |

-20-80 |

|

Safety overload |

%R.C. |

150 |

|

Extreme overload |

%R.C. |

200 |

|

Cable line specifications |

m |

Φ5*5m |

|

Cable limit pull force |

N |

98 |

|

TEDS |

selectable |

|

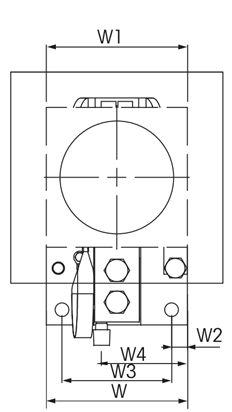

Dimension (mm)

|

Range |

D |

H |

H1 |

H2 |

H3 |

H4 |

L |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

W |

W1 |

W2 |

W3 |

W4 |

A |

|

300kg/500kg/1T |

11.2 |

105.2 |

19.1 |

12.7 |

50.9 |

15 |

177.9 |

114.4 |

89.0 |

12.7 |

152.4 |

12.7 |

185.6 |

114.4 |

114.4 |

12.7 |

89.0 |

66.6 |

M10 |

|

3T |

11.2 |

51.3 |

69.7 |

||||||||||||||||

|

5T |

17.5 |

136.6 |

25.4 |

19.1 |

70.3 |

20 |

235.0 |

152.4 |

101.6 |

25.4 |

184.2 |

25.4 |

- |

152.4 |

152.4 |

25.4 |

101.6 |

91.7 |

M16 |

Force Diagram

Product Anatomy Diagram

Installation

Design

Drawing 3D Models

Machining center

CNC machining, automated production, high efficiency

Inspection

Each process is strictly inspected

Patches

Fine production, dust-free micro-pasting

Calibration And Testing

Professional calibration and testing equipment

Application

Can be integrated into truck scales, weighbridges, and vehicle weighing systems due to its high accuracy and capacity.3

The cantilever beam design offers advantages like high accuracy, simultaneous tension/compression measurement, compact size, easy installation, and suitability for harsh environments. This makes the module suitable for various industrial weighing applications requiring reliable and precise force measurement.

1.Tank and silo weighing

- Suitable for weighing and level monitoring of tanks, silos, and reactors containing liquids or bulk solids.23

- The compact design allows easy installation on tanks and vessels.

2. Weighing of large structures

- Can be used to weigh and monitor the weight of large structures like machinery, equipment, or platforms.1

- The ability to measure both tension and compression forces makes it versatile.

3. Process weighing and batching

- Applicable in process industries for weighing ingredients, raw materials, or final products during batching operations.

- Truck and vehicle weighing

FAQ

Q: Can we use our own logo?

Q: Could I visit your factory?

Q: How can you make delivery ?

Q: What is the payment term ?